Is the MZS1065 Zoom Stereo Microscope the Best Choice for Precision Inspection?

At MTscope, we understand the frustration engineers face daily: trying to solder a microscopic component while battling a microscope that leaves no room for your

| Optical Mag. | 0.75X~5X |

|---|---|

| Zoom Ratio | 6.7:1 |

| Mounting Size | φ45mm |

| Working Distance | 82mm |

| Magnification | NA | DOF | Resolution | Distortion | Fixed Dim.:Φ45mm |

| 0.75X | 0.03 | 1.8mm | 11.2μm | 0.26% | |

| 2.0X | 0.067 | 0.30mm | 5.0μm | 0.31% | |

| 5.0X | 0.097 | 0.08mm | 3.5μm | 0.12% |

| Objectives | Item | CCD adapter | ||||||

| 0.3X | 0.4X | 0.5X | 0.67X | 1X | 1.5X | 2X | ||

| 0.3X | Optical. Mag. | 0.07X~0.45X | 0.09X~0.6X | 0.11X~0.75X | 0.15X~1X | 0.225X~1.5X | 0.34X~2.25X | 0.45X~3X |

| WD:293mm | FOV(mm) | 51.4X68.6~8X10.67 | 40X53.33~6X8 | 32.7X43.6~4.8X6.4 | 24X32~3.6X4.8 | 16X21.3~2.4X3.2 | 10.6X14.12~1.6X2.13 | 8X10.67~1.2X1.6 |

| 0.5X | Optical. Mag. | 0.11X~0.75X | 0.15X~1X | 0.19X~1.25X | 0.25X~1.675X | 0.375X~2.5X | 0.56X~3.75X | 0.75X~5X |

| WD:175mm | FOV(mm) | 32.7X43.6~4.8X6.4 | 24X32~3.6X4.8 | 18.9X25.3~2.88X3.84 | 14.4X19.2~2.15X2.9 | 9.6X12.8~1.44X1.92 | 6.4X8.6~0.96X1.28 | 4.8X6.4~0.72X0.96 |

| 0.75X WD:117mm | Optical. Mag. | 0.17X~1.125X | 0.225X~1.5X | 0.28X~1.875X | 0.4X~2.5X | 0.56X~3.75X | 0.84X~5.625X | 1.125X~7.5X |

| FOV(mm) | 21.2X28.2~3.2X4.27 | 16X21.33~2.4X3.2 | 12.9X17.1~1.92 X2.56 | 9X12~1.44 X1.92 | 6.4X8.6~0.96X1.28 | 4.3X5.7~0.64X0.85 | 3.2X4.27~0.48X0.64 | |

| 1X | Optical. Mag. | 0.225X~1.5X | 0.3X~2X | 0.375X~2. 5X | 0.5X~3.35X | 0.75X~5X | 1.125X~7.5X | 1.5X~10X |

| WD:82mm | FOV(mm) | 16X21.3~2.4X3.2 | 12X16~1.8X2.4 | 9.6X12.8~1.44X1.92 | 7.2X9.6~1.07X1.4 | 4.8X6.4~0.72X0.96 | 3.2X4.27~0.48X0.64 | 2.4X3.2~0.36X0.48 |

| 1.5X | Optical. Mag. | 0.34X~2.25X | 0.45X~3X | 0.5625X~3.75X | 0.75X~5X | 1.125X~7.5X | 1.6875X~11.25X | 2.25X~15X |

| WD:54mm | FOV(mm) | 10.6X14.1~1.6X2.13 | 8X10.67~1.2X1.6 | 6.4X8.53~0.96X1.28 | 4.8X6.4~0.72X0.96 | 3.2X4.27~0.48X0.64 | 2.13X2.84~0.32X0.43 | 1.6X2.13~0.24X0.32 |

| 2X | Optical. Mag. | 0.45X~3X | 0.6X~4X | 0.75X~5X | 1X~6.7X | 1.5X~10X | 2.25X~15X | 3X~20X |

| WD:35mm | FOV(mm) | 8X10.7~1.2X1.6 | 6X8~0.9X1.2 | 4.8X6.4~0.72X0.96 | 3.6X4.8~0.54X0.72 | 2.4X3.2~0.36X0.48 | 1.6X2.1~0.24X0.32 | 1.2X1.6~0.18X0.24 |

| 4.5X | Optical. Mag. | 1.01X~6.75X | 1.35X~9X | 1.69X~11.25X | 2.26X~15.07X | 3.37X~22.5X | 5.06X~33.75X | 6.75X~45X |

| WD:16mm | FOV(mm) | 3.56X4.74~0.53X0.71 | 2.67X3.56~0.4X0.53 | 2.13X2.84~0.32X0.43 | 1.59X2.12~0.24X0.32 | 1.07X1.42~0.16X0.21 | 0.71X0.95~0.11X0.14 | 0.53X0.71~0.08X0.11 |

| Zoom body magnification range: 0.75X~5X | ||||||||

| Auxiliary illuminators | MLC1000,MLR25 |

| CCD adapters | 0.4X, 0.5X, 0.67X, 1.0X(Standard outfits),1.5X,2.0X |

| Objectives | 0.3X,0.4X,0.5X,0.6X,0.75X,0.9X, |

| Infinite farness metallographic lens | Nikon, Olympus, Mitutoyo |

| Stands | SD1-D ~ SD18-D |

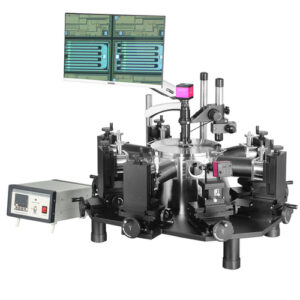

The MZDH0850 zoom lenses are engineered for high-performance optical systems where clarity, resolution, and flexibility are paramount. Perfect for industries such as semiconductor inspection, LCD production, and electronics, these lenses are designed to provide consistent, high-quality imaging across a wide range of applications.

The MZDH0850 series offers multiple configurations to cater to your specific requirements:

It has advantages on the applications as below:

The MZDH0850 series is designed for a variety of high-precision applications across multiple industries. Below are some key use cases:

The maximum magnification of the MZDH0850 series is 45X with the standard zoom objective lens and CCD adaptors. However, the system supports various objective lenses with different magnifications, allowing you to customize it for your specific needs.

Yes, the MZDH0850-D model features fixed magnification with precise positioning, making it suitable for both 2D and 3D measurements, especially when accurate repeatability is required.

Yes, certain models like the MZDH0850-D offer motorized zoom with stepper motors for precise magnification adjustments. This ensures accurate and repeatable zoom changes, particularly useful for automated processes.

The working distance varies depending on the objective lens used. For example, with the 0.75X objective lens, the working distance is 117mm, providing a good balance between magnification and depth of field.

Yes, the MZDH0850 series supports a variety of CCD and CMOS cameras, and the system includes adapters for different camera interfaces. You can easily integrate a camera to capture high-quality images or videos for documentation or analysis. However, you need to learn how to adjust the focal length and centre between the zoom lenses and the camera to ensure parfocal.

If you have interest to get the details, please contact us.

Absolutely. The MZDH0850 series features coaxial illumination, which provides uniform lighting even on reflective surfaces like metals and wafer. This ensures clear, high-contrast images without the need for additional external lighting.

The MZDH0850 supports both LED and fiber optic cold light sources. The coaxial illumination (MLC1000) is ideal for high-contrast imaging, especially for reflective materials. Additionally, adjustable LED lighting (MLR25) is available for flexible illumination.

Yes, the MZDH0850 series offers customizable options including a range of objective lenses, CCD adaptors, lighting systems, and camera interfaces. We can help you configure the system to suit your unique application needs.

The MZDH0850 is highly beneficial for industries such as electronics, semiconductors, optical components manufacturing, material science, and medical device production. Its versatility and high-resolution capabilities make it suitable for a wide range of precision inspection and measurement tasks.

The MZDH0850 is designed for easy installation and setup. Its compact design and modular components simplify the integration process, and we provide support for installation and calibration if needed.

At MTscope, we understand the frustration engineers face daily: trying to solder a microscopic component while battling a microscope that leaves no room for your

As an optical engineer at Guilin Microtech (MTO), I have often observed that in the world of semiconductor and micro-CNC machining, the difference between “good”

In our years in the optical instruments industry, we’ve seen countless companies struggle with one critical decision: choosing the right microscope. This isn’t just about

Table of Contents What Are the Essential Functions of Microscopes in Wafer Probe Stations? Have you ever wondered what makes a microscope indispensable for wafer

Table of Contents 1. What Challenge Did We Face? In this case study, we explore how a Weld Seam Inspection Monocular Lens helps manufacturers ensure

We are thrilled to announce our participation in the LASER World of PHOTONICS CHINA 2025, Asia’s premier trade fair for the photonics industry. This event will